All aluminum alloys can be extruded, but there are some factors to consider when determining whether a particular part can be successfully extruded. Factors such as size, shape, alloy, tolerance, scrap rate, extrusion ratio and tongue-and-groove ratio. And whether you should use forward or reverse extrusion for production.

The forward extrusion process is the most commonly used process in the extrusion industry. It is simpler in design and more flexible in profile manufacturing.

The benefits of the reverse process (often called reverse extrusion) include reduced friction and improved consistency. The enhanced consistency is manifested in the dimensional and metallurgical structure along the length of the extruded profile. The reverse process is used to achieve more consistent workability, for example, in rod and bar products through more consistent metallurgical structure. Enhanced dimensional tolerances help rods used as screw machine billets.

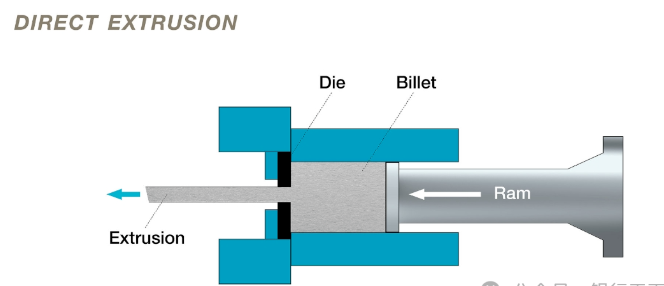

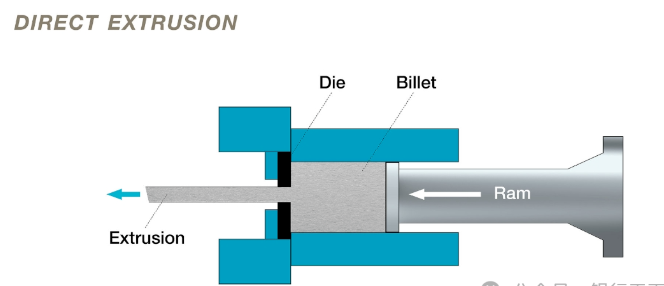

Forward Extrusion

In the forward extrusion process, a heated aluminum billet is pushed through a fixed die by a cylinder head to form a specified shape. The aluminum flows in the direction of the plunger's travel, creating friction between the billet and the container. This increases the workload during the extruder cycle, resulting in higher temperatures before and after the extruder. This variation in work and temperature along the length of the extrusion results in a change in the metallurgical structure along the length of the extrusion. The temperature variation and increased work along the length affect the grain structure and microstructure, which are important for machinability. Dimensions are affected by the pressure on the die of the extruded profile, which decreases during the extrusion cycle. Pressures in the indirect process are highest at the front of the extrusion due to the additional force required to overcome the pressure.

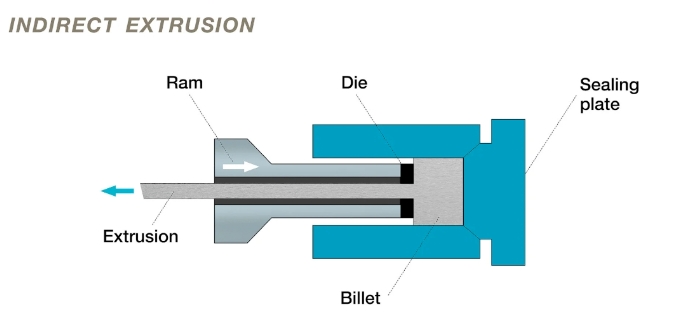

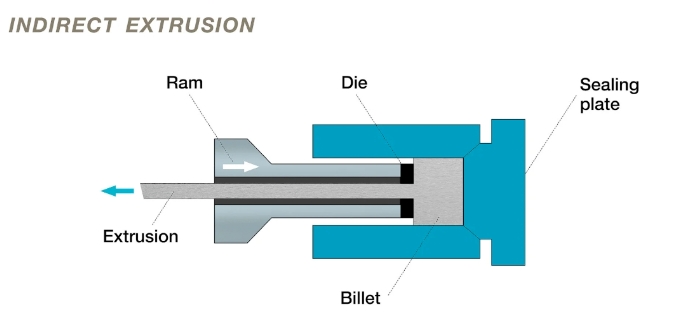

Reverse Extrusion

In the direct extrusion process, as described above, the die is stationary and the ram applies pressure to the aluminum bar. In the reverse extrusion method, the extrusion head carries the die and applies pressure to the stationary aluminum bar in the opposite direction of the extrusion.

There can be variations on this concept, but in all cases the aluminum bar is stationary relative to the container. Therefore, there is no billet-to-container friction effect and the forces in the extrusion process remain relatively constant from the front to the back of the extrusion. As an added benefit, the work also remains relatively constant, eliminating friction in the direct process.

Advantages and Disadvantages of Reverse Extrusion The result of reverse extrusion is a more consistent work and less temperature variation throughout the length of the extrusion. This provides more consistent dimensions, grain structure, and mechanical properties. The reverse process does have its pros and cons. For example, since there is no friction, anything on the surface of the aluminum bar will affect the extrusion surface. This requires that the aluminum bar must be de-cast and then kept relatively free of dirt and oil.

Another disadvantage is that the die must be supported during the extrusion process and the extrudate allowed to pass through that support. Therefore, the profile size through the round diameter is greatly reduced. Reduced Process Variation Along the Extrusion Length The back-extrusion process has a long history of research that has scientifically provided the metallurgical benefits and reasons for the reduced dimensional variation. We continue to use the science behind the back-extrusion process to produce products that benefit from the reduced process variation during the extrusion process. Products such as rods and bars have excellent re-machinability due to the reduced variation.

Address : NO.7 Huihe Road, Qianzhou Industry park, Huishan District, Wuxi City, China

Address : NO.7 Huihe Road, Qianzhou Industry park, Huishan District, Wuxi City, China

IPv6 network supported

IPv6 network supported