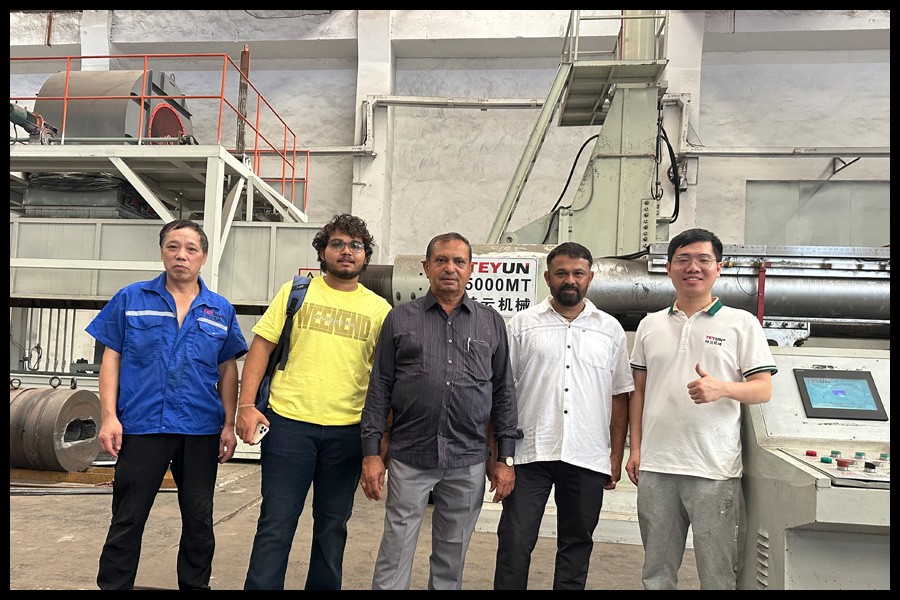

Customers from India visit our factory

April 22, 2023

3600ton aluminum extrusion press is ready! Welcome Indian customer Mr Taniqsh to visit Teyun!Mr Taniqsh has ordered our 3600t aluminum extrusion press whole about 5 months ago. Due to the COVID-19 before, Mr Taniqsh can not come to China to talk with us directly, but because of our professional plan, he finally choosed us and release the order to us. Now the 3600ton aluminum extrusion main press is almost finished, he came to Teyun to check his machine. We show the client around the factory including the producing process, the engineers' design ,the sale team and also the after-sale service, so that the client can have a good knowledge of our Teyun. Our engineer sale James introduced the cliet to our production line, explained to the client that we use state-of-the-art technology to ensure consistent and accurate dimensions of our profiles. At the same time we also explained the extrusion process, the different alloys we use, and the properties and advantages of our products. Then we showed the client our tooling department, where we create custom dies for specific profiles. There, Mr Taniqsh saw the precision required to create these molds and how we achieve high-quality results. Some of our dies are used to create complex profiles, which allow us to cater to a wide range of customer requirements. After the that, we tooke the client to our quality control department, where we have a well-equipped laboratory to check and test our extruded aluminum profiles. According to this visit, the client has learned about our stringent quality control measures, as we test our machine for strength, durability, and dimensional accuracy. Also the client talked with our sales team, who addressed the questions Mr Taniqsh has regarding our machines and services. Mr Taniqsh is very satified with this trip to our Teyun and our machine quality, he told us he is very looking forward with the final aluminum extrusion line to his factory!

Read More

Address : NO.7 Huihe Road, Qianzhou Industry park, Huishan District, Wuxi City, China

Address : NO.7 Huihe Road, Qianzhou Industry park, Huishan District, Wuxi City, China

August 02, 2023

August 02, 2023

IPv6 network supported

IPv6 network supported